Testing Capabilities

CMM

A coordinate measuring machine (CMM) is a device that measures the geometry of physical objects by sensing discrete points on the surface of the object with a probe. Various types of probes are used in CMMs, including mechanical, optical, laser, and white light. Depending on the machine, the probe position may be manually controlled by an operator or it may be computer controlled. CMMs typically specify a probe's position in terms of its displacement from a reference position in a three-dimensional Cartesian coordinate system (i.e., with XYZ axes). In addition to moving the probe along the X, Y, and Z axes, many machines also allow the probe angle to be controlled to allow measurement of surfaces that would otherwise be unreachable

MOISTURE ANALYZE

A Moisture Analyzer performs moisture analysis by using the ‘loss on drying’ (LOD) method. This is the most common method for moisture analysis.

The sample is weighed using the Moisture Analyzer’s balance unit before and after the removal of moisture. This is done by the continuous recording of the weight while the sample is heated and dried using a halogen lamp or other infrared radiator.

When the sample no longer loses weight, the difference between the two weights is measured, which is used to calculate the moisture content. This is also known as the thermos-gravimetric principle.

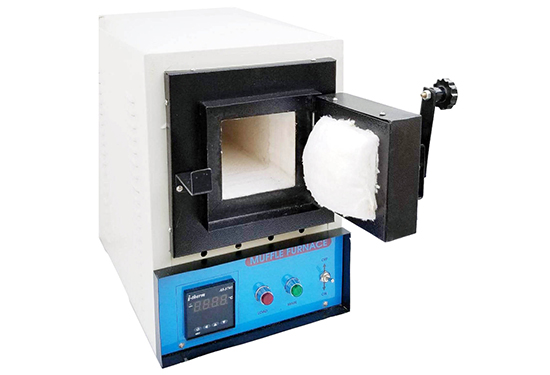

MUFFLE FURNACE

Our “Ash Test” method is used to determine the ash residual in molded Rubber and Plastic (polymer) Testing Instruments. The direct calcinations method involves taking a known amount of sample into a pre-conditioned and pre-weighed crucible, burning the organic matter in an air atmosphere at temperatures around 600ºF (pre-burn), heating the remaining residue at 800ºF, and weighing the crucible after it has been cooled to room temperature

in a desiccators. The procedure is repeated until a constant mass is reached.

The ash test result is expressed as % ash, calculated from the mass of the ash (Mash) and the initial mass of the sample (Msample). We can report the net ash in parts per million (ppm) or equivalently mg/kg.

OVAN

A hot air oven is a type of dry heat sterilization. Dry heat sterilization is used on equipment that cannot be wet and on material that will not melt, catch fire, or change form when exposed to high temperatures. Moist heat sterilization uses water to boil items or steam them to sterilize and doesn't take as long as dry heat sterilization.

Hot air ovens use extremely high temperatures over several hours to destroy microorganisms and bacterial spores. The ovens use conduction to sterilize items by heating the outside surfaces of the item, which then absorbs the heat and moves it towards the center of the item.

THERMAL CHAMBER

Thermal shock test chamber is used to test the bearing extent of the material in an instant and continuous high temperature and extremely low temperature environment that is in the shortest time to test its thermal expansion and contraction caused by chemical change or physical harm. Application Objects, including metal, plastic, rubber, electronics and other materials can be used as a basis to improve their products reference.

Working Principle of three zone thermal shock test chamber: Test products are placed in test box, in adopt upper, middle and lower box structure, the upper box is high temperature box, the middle box is test box, the lower box is low temperature box. The Upper high temperature box and low temperature box are able to set the test temperature and extreme temperature condition. When use low temperature chamber test, the low temperature door be opened with test chamber to test working space and process low

temperature test. Switch to the high temperature test, the door of low temperature box door is closed, the high temperature box and test box to be a new test working space, the mechanical action of switch can be completed in less than 1s, and the temperature can be fast stable. During the whole test processing, the sample is not moved at all and do need operator intervention.

UNIVERSAL TESTING MACHIN

A universal testing machine (UTM), also known as a universal tester, materials testing machine or materials test frame, is used to test the tensile strength and compressive strength of materials. An earlier name for a tensile testing machine is a tensometer. The "universal" part of the name reflects that it can perform many standard tensile and compression tests on materials, components, and structures.

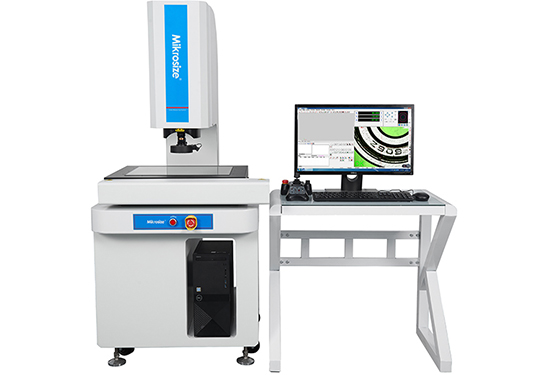

VMS

1. Video Measuring System is a Z-axis Auto Focus.

2. Powerful Measuring Software with auto tracing-edge function,multi-output report

3. Sub-pixel segmentation technology improves the ability of image boundary resolution.

4. The surface cold light source can be used to measure the complex work piece.

5. With laser pointer, easy to find the specific location of the measured work piece.

6. Stable Granite workbench with “00” Grade.

7. German Made High Precision Polish Rod and Bearing

8. High Resolution Video System

9. Measuring Probe is optional for simple 3D purpose.